Copper

What is copper?

Copper is a chemical element and, in terms of cultural history, is one of the first metals used by man and is one of our oldest building materials. Nowadays copper is one of the most widely used materials for a wide range of applications. Due to its very good workability and outstanding durability, copper has enjoyed great popularity as a building material for centuries and many historic buildings are witnesses to this history and can be experience in our daily environment.

Today, ecological considerations play a role just as important in the choice of building materials as technical and aesthetic aspects. This makes copper, with its excellent recycling properties, also a modern building material. Copper can be 100% recycled as often as desired, without any loss of quality. Thus Copper meets the requirements for a sustainable use of building materials.

Range of products / variants

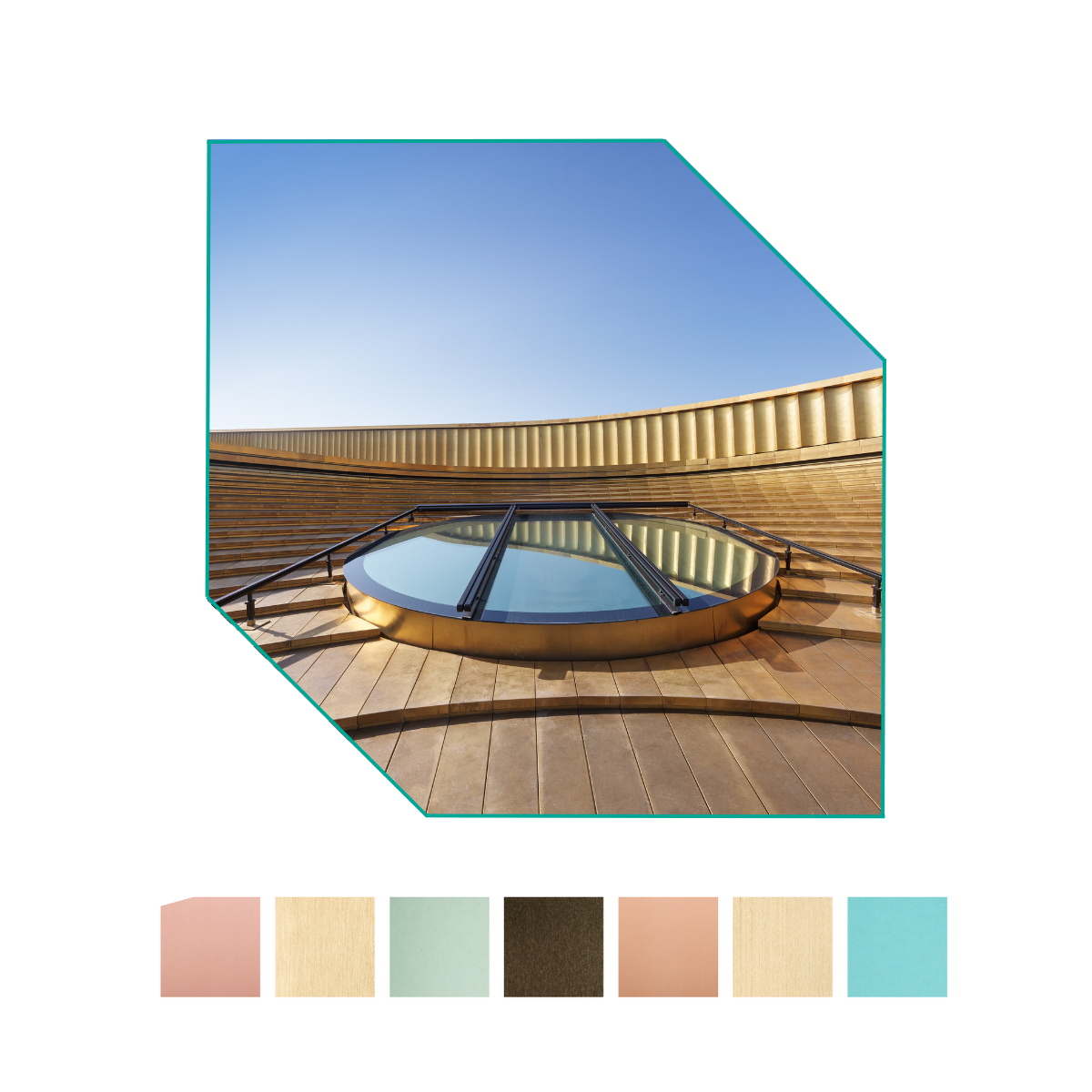

VM Building Solutions has been actively promoting and selling a variety of natural copper products for many years and continues to do so.

In 2024, the company signed an exclusive agreement to become the sole distributor of the Nordic Copper range. This collection includes 14 distinct material and surface variations, featuring mill-finished and pre-weathered copper, brass, and bronze, along with eight unique patina finishes. Additionally, Nordic Royal enhances the range as a special aluminum bronze with a lasting golden appearance.

What is Nordic Copper ?

Nordic Copper is the product range for architectural applications, such as facades roofs and interiors, made by Aurubis. The unrivaled range of factory-applied surface treatments provides copper and brass with various stages of oxidation and patination immediately. Nordic Copper stands for individual architectural solutions, a long life cycle for buildings and a responsible legacy for future generations and is exclusively available from VM Building Solutions.

Nordic Brass

Nordic Royal

Nordic Green Living 2

Nordic Blue Living 1

Nordic Brown Light

Nordic Brass Weatherd

Nordic Green Trad.

Nordic Turquoise

Nordic Blue Living 2

Nordic Brown

Nordic Bronze

Nordic Green Living 1

Nordic Blue Traditional

Nordic Blue Living 3

Why choose Nordic Copper?

All Nordic Copper products offer the benefits of:

- Protection by its patina against corrosion in any atmospheric conditions, durable and problem-free with no maintenance

- Exceptional, indefinite lifespan demonstrated over hundreds of years

- Cost-efficient substrates and low ‘whole-life’ costs

- Easy malleability at any temperature and no brittleness in cold weather

- Low thermal movement and high melting point, which prevents stretching in hot weather

- Non-toxic and safe to work with

.png)

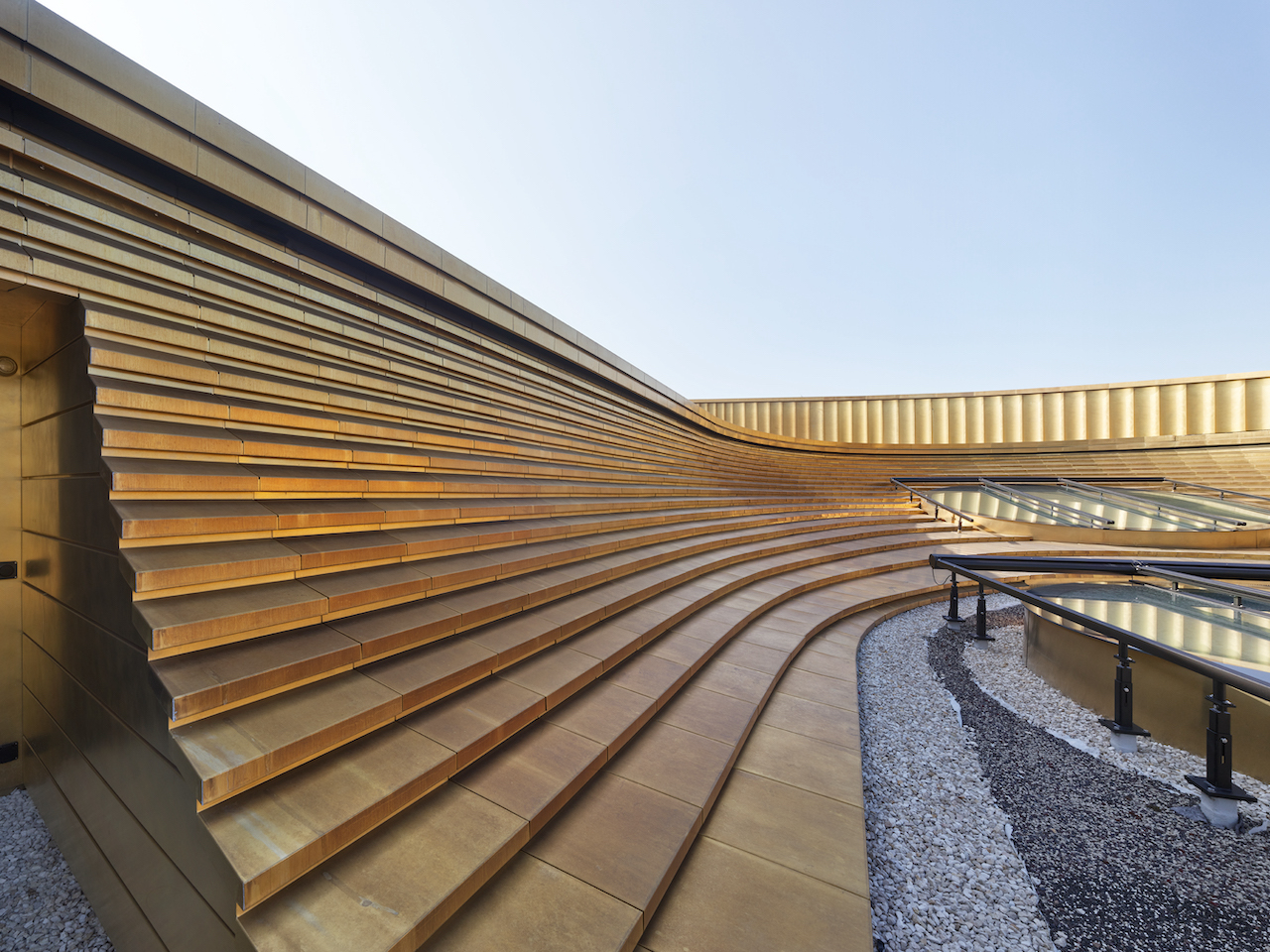

High quality facade and roofing

Curious about the possibilities of Nordic Copper for your roof façade or interior? Ask for samples or tell us more about your project.

Documentation

Please enter your E-mail address. We will send you the download link by mail.

Sample request

Would you like samples of our surface finishes or have any questions about our products? Fill out this form, and our team will get back to you as soon as possible.